|

|

|

|

|

|

|

Features

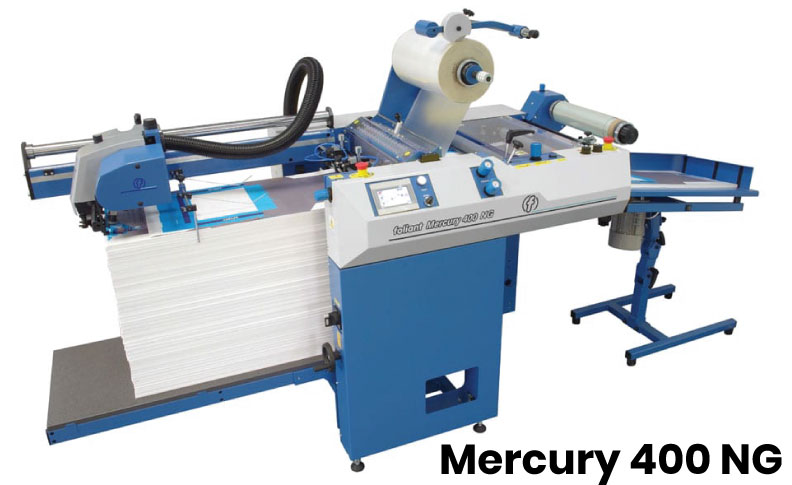

Mercury 400 NG-

The Foliant Mercury 400 NG is a very Compact Industrial Laminating

Machine, constructed for a heavy-duty digital and offset output. It is

equipped with a Foliant integrated suction feeder and a high-speed bump

separator.

Several options are available for the Foliant Mercury 400 NG

machine – Foliant Foiler, non-sticky pressure roller, pallet stacker,

etc.

Due to its high-pressure system, the format and the performance of

the machine is suitable for all jobs – all kinds of digitally printed

sheets for lamination and high volumes of offset printed sheets, size

14″ x 20″ for lamination.

The machine’s maximum speed is up to 88

feet/minute, while performance is 3,240 sheets per hour of 14″x 20″

portrait (white paper 200 gsm).

Mercury 400 NG Brochure:

Mercury 530 NG-

The Foliant Mercury 530 NG is a very Compact Industrial Laminating

Machine, constructed for heavy-duty digital and offset output. It is

equipped with a Foliant integrated suction feeder and a high-speed bump

separator.

Several options are available for the Foliant Mercury 530 NG

machine – Foliant Foiler, non-sticky pressure roller, motorized pallet

stacker, extended sheets laminating module, etc.

Due to its

high-pressure system, format and performanc, the machine is suitable for

all jobs – all kinds of digitally printed sheets for lamination and

high volumes of offset printed sheets, 19.7″ x 27.8″ for lamination.

The

machine’s maximum speed is up to 88 feet/minute, while performance is

2,300 sheets per hour of 19.7″ x 27.8″ portrait (white paper 200 gsm).

Mercury 530 NG Brochure:

Mercury 760 NG-

The FOLIANT Mercury 760 NG is a very compact and fast industrial laminating machine constructed for heavy-duty work with an integrated suction feeder, high-speed bump separator and an optional pallet stacker.

The machine’s maximum speed is up to 65 ft/min., while maximum performance is 1,200 sheets per hour of 27.8” x 39.4” portrait or 2,400 sheets per hour of 19.7” x 27.8” landscape (white paper 200 gsm).

Advantages at a Glance

- Easy operation

- Equipped with a rising back pile separation stream feeder with a Foliant suction feed head

- Single-sided thermal industrial laminator

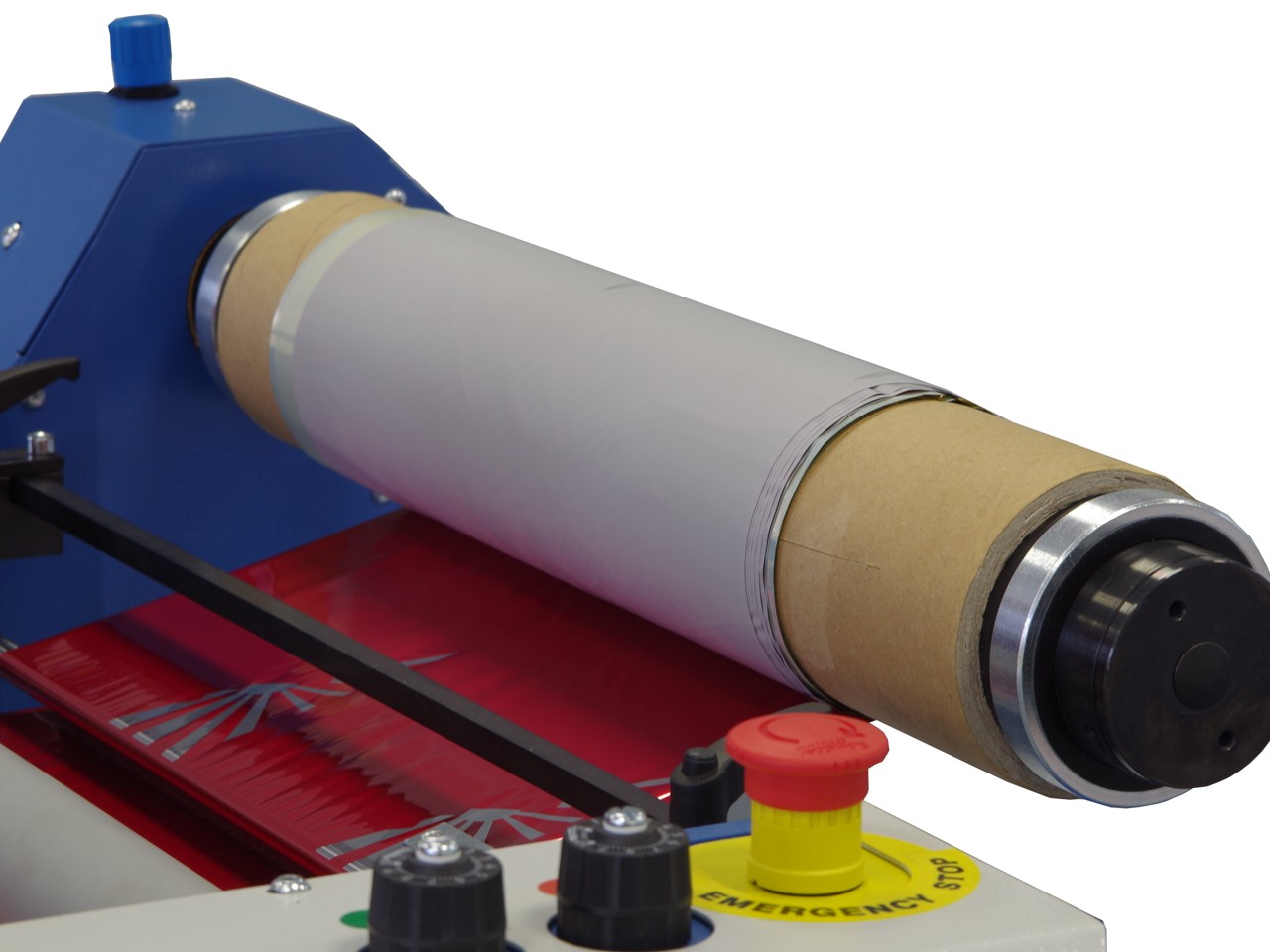

- Film is mounted on a quick-change shaft with a film tension control breaker

- Film holder unit is equipped with a trim slitter and perforation wheel

- Pressure is pneumatically adjustable

- De-curl blade for offset printed sheets

- De-curl roller for digitally printed sheets

- OMRON programmable logic controller for easy automation

Options:

jogger,

pallet stacker,

non-sticky pressure roller,

PET lamination

module,

Foliant Foiler,

film loader/manipulator,

film micro adjustment

air shaft

Options:

jogger,

pallet stacker,

non-sticky pressure roller,

PET lamination

module,

Foliant Foiler,

film loader/manipulator,

film micro adjustment

air shaft

Options:

Jogger

Keeps the finished pieces neatly stacked for future handling

Pallet Stackers

Motorized receding stacker with a pallet on wheels to permit less handling during runs. (No longer painted yellow)

Mercury 760 NG Version of Pallet Stacker:

Controlled from main machine

Non-sticky pressure roller

The standard pressure roller is replaced with a coated roller so adhesive won't stick to it and pieces with windows are possible when running single-sided lamination

PET lamination

module

The PET Films Application Module is integrated inside the separator for the PET films (max. 25 microns) processing.

Foliant Foiler

Sleeking (Digital Foil) can be performed on these models.

Film loader/manipulator

For easy loading of heavy film rolls

There are several more options beyond the ones shown above, please contact us for a full list.

|

|

|

|

|

|

|